"After Hours" Glass - Whitall Tatum Company

Reprinted from "Crown Jewels of the Wire", June 1986, page 27

In 1922, the prestigious glass company, Whitall Tatum, of Millville, N.J.,

began to manufacture glass insulators. The insulator plant, subsequently owned

by the Armstrong Cork Co., and later, by the Kerr Glass Manufacturing Co.,

became one of the world's most prolific producers of insulators. It is estimated

that close to 200 million insulators had been produced up to the time Kerr

ceased production at the plant around l977/78.

Not included in the official production records of these three companies are

the several hundred insulators that were made at the plant after-hours. I have

come across a variety of "non-standard" after-hours insulators.

The purpose of this article is to begin to record the existence of these

odd-ball insulators and to try to explain how, and why, they were made. As

friendly basements and garages are explored, other examples of "after-hours

production" may surface. If so, such examples should be added to this list.

Each of the insulators I have listed were discussed with Rich Wentzel and his

father, Don Wentzel. Both have worked for the Wheaton Glass Company, and in that

capacity, they came to know many of the management level employees who worked

for Whitall Tatum/Armstrong/Kerr companies, as well as a lot about production

activities at the plant. I am deeply indebted to Rich and Don for sharing the

insights of their years of affiliation with Whitall Tatum and its successors.

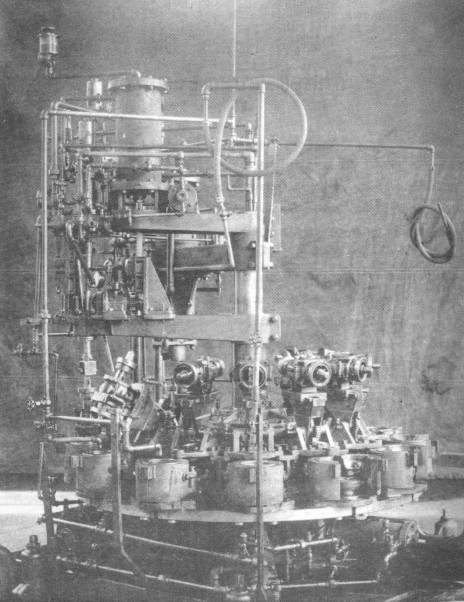

Large Image (391 Kb)

Whitall Tatum Type C insulator machine. Notice the open mold at the lower

right center of the picture. This is certainly an invitation to find out what

kind of variations can be made with the regular insulators. The units that make

the threads are poised above the molds.

AFTER-HOURS INSULATORS

1. The cobalt-streaked CD 155. There was a small amount of cobalt left from

making cobalt glassware, at the end of the day. Workers got permission to toss

some cobalt onto the clear CD 155's they had been working with that day. The

device which stains color-producing agents into the glass was not turned on at

that time. This resulted in a splotch effect rather than a complete

cobalt-colored insulator. Between 150 and 200 insulators were stained in this

manner.

2. Titanium coated CD 155. (Circa 1973.) This is one of the most striking

insulators I have seen. Titanate, a salt or ester of titanic acid, was sprayed

on the insulator before the annealing process. This resulted in a clear-silver

coating over the entire insulator, and the skirt and areas of the glass that

curve have a very light carnival-like color. The color actually has the tones

you see when engine oil has dripped into a water puddle. The colors vary in

intensity with the amount of light on the insulator. The color does not come

off, as far as I can determine.

This after-hours activity is in fact similar to the process used in bottle

making called, titanizing. The titanizing process was developed in Great

Britain. It consisted of spraying bottles with a titanium compound before

annealing, while the bottles were red hot. Part of the compound volatilizes,

leaving a very thin layer of titanium oxide, which is soluble in glass. This

results in an increase in the working life of the bottle by reducing friction

and increasing resistance to the formation of tiny cracks in treated glass.

3. Frosted insulators, CD's 128, 155, 167 and 214. Frosting was done by two

methods: Sandblasting, and acid bath. Frosting was done on complete insulators,

for the most part. There are examples of frosting done in conjunction with

irregularities such as coin imprints and the top off. Some very pretty frosting

has been found, as well as some very crude efforts.

4. Solid glass, CD 154. (No thread hole or inner skirt.) The one I have is

ice blue/green in color and has hundreds of tiny bubbles in, and above, the wire

groove area. The bottom has marks that show how the insulator rested when it was

finished. The solid glass, ice effect, makes this a very pretty insulator.

This insulator is the result of the process which brought the insulator mold

up to operating temperature. Molten glass filled the mold. The inner skirt ring

and the threaded pin were not used. When the mold was hot, the glass was removed

and discarded. In the case of the one I have, the solid glass insulator was

somehow allowed to go through the annealing process, After that, it apparently

was spirited out of the plant. At least one clear one exists. There may be

others.

5. Insulators without tops, CD's 122, 128, 129, and 155. The tops of these

insulators were not cut off -- they were made without tops. The portion of the

insulator mold that contained the profile of the top was not used, resulting in

a flat dome. This flat-domed insulator made an attractive and unusual candle

holder.

6. Coin imprints in the top of domes, CD's 128 and 129. Since the insulator

is in the mold upside-down, a coin is laid in the bottom of the mold and the

glass surrounds the coin. When finished, the coin is flicked out of the glass by

using a sharp tool, leaving an imprint of a variety of coins, either heads or

tails. I have seen imprints of all American coins except the dollar.

There are also instances of coins which have been entirely embedded in

insulators.

7. Insulator halves. These insulators have been cut in half, vertically, to

enable laboratory technicians to check glass thickness through various

cross-sectional areas of the insulators. Instead of the trash pile, some of

these insulators have found their way into homes. Properly weighted, these

halves make unusual and attractive book ends.

One final note. The blueprint of the 1927, Type D, insulator machine shows it to be 105-7/8 inches tall. It is a wonder that

such a metal-monster can produce such fine pieces of glass.

I would be interested in any comments about the information presented in this article.

Copyright 1986

Ward Lindstrom

Turnersville, NJ

|